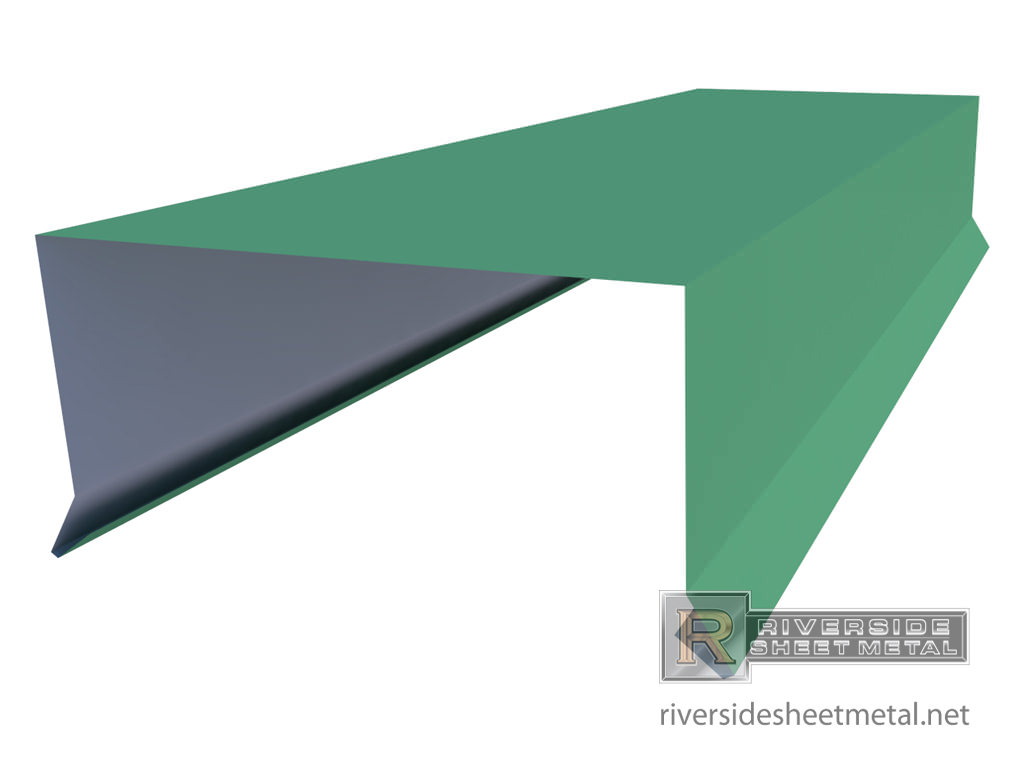

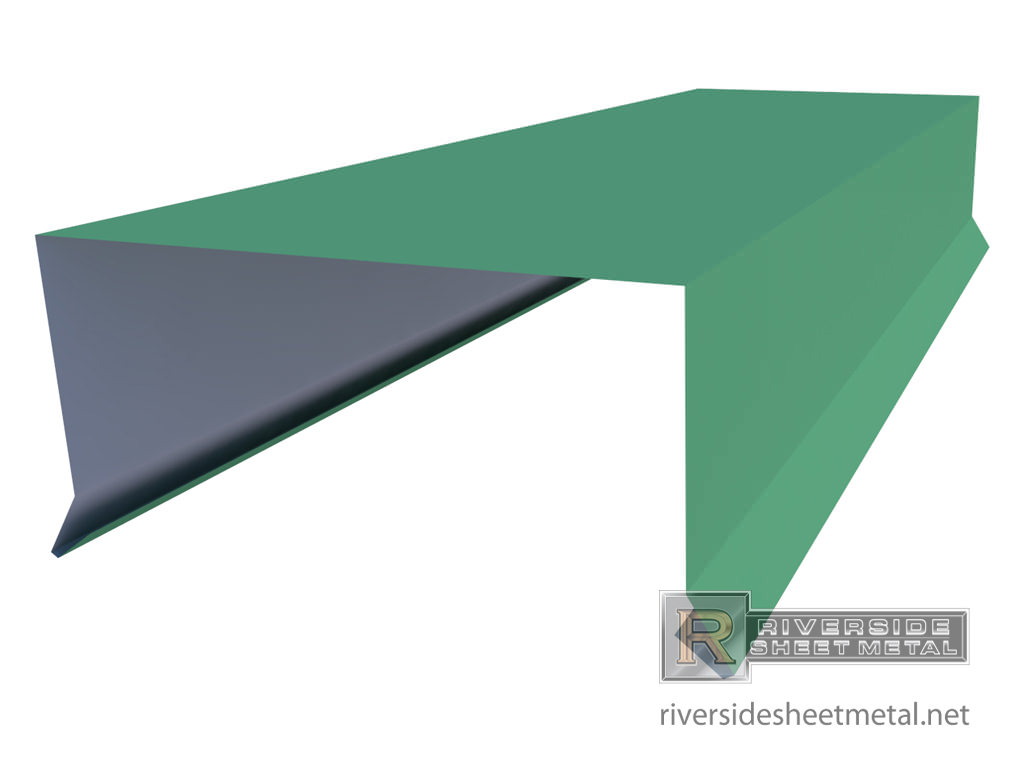

Roof leg and a 7 in.

Flash parapit wall to high roof wall.

No air control in either the roof assembly or the wall assembly.

On the inside face of a parapet or wherever a masonry wall intersects a lower roof i have seen cases where the masonry flashing exits the wall one or more courses above the top of the retaining bar for the roof base flashing.

Copper base flashing which extends at least 8 up the wall.

On walls greater than 36 inches high membrane wall flashing sheets are suggested to be strapped i e installed vertically.

No vapor control layer and thermal bridging everywhere.

Wsrca suggests for walls 24 inches and taller that wall cladding be considered in lieu of membrane wall flashings per detail tp 8a.

Ah but not in the way you think.

Mortar bridges below the through wall flashing may be allowing water to cross the cavity into the backup wall.

Bigger step flashing is better.

How to attach flashing to a parapet wall.

Finally the housewrap can be laid up on the wall to cover the top of the kickout diverter and step flashings.

This detail may be used where wall heights are 24 48 inches above roof surface.

Air leakage into and out of everything and everywhere.

Water may be entering the coping at the top of the parapet or entering the roof side of the parapet.

Water from either of these locations may bypass flashing and enter the backup wall directly.

Accounting for roof penetrations when dealing with parapet walls the extra material needed to cover the vertical surface of the inside face of the parapet isn t the only added factor to take into consideration.

Fasten outside face with continuous concealed clip type fasteners or with two concealed discontinuous clips or cladding screws evenly spaced between seams.

Many apartments and condominiums have flat sections of roof designed for air conditioning or other roof mounted equipment.

The profile of specific components their.

The installation of the coping to wall termination provides waterproofing protection and allows for differential movement between the two construction components.

This detail shows a flashing condition at a vertical wall or parapet.

Cut to form a 25mm 1 wide flange for seam fabrication at cap flashing wall transitions.

The counterflashing laps the base flashing a minimum of 3.

The narrower step flashing just isn t wide enough to protect the intersection fully.

See sbs roof systems 12 6 cap flashings base flashings and reglets parallel standards are shown.

And to make matters worse structurally we also tend to have some issues.

Prior to the installation of the parapet coping a metal flashing material shall be adhered to the structural wall.

Architects of ultra modern.

The roofing squares are locked into a 20 oz.

The metal flashing shall lap the parapet wall.

No membrane under the parapet flashing.