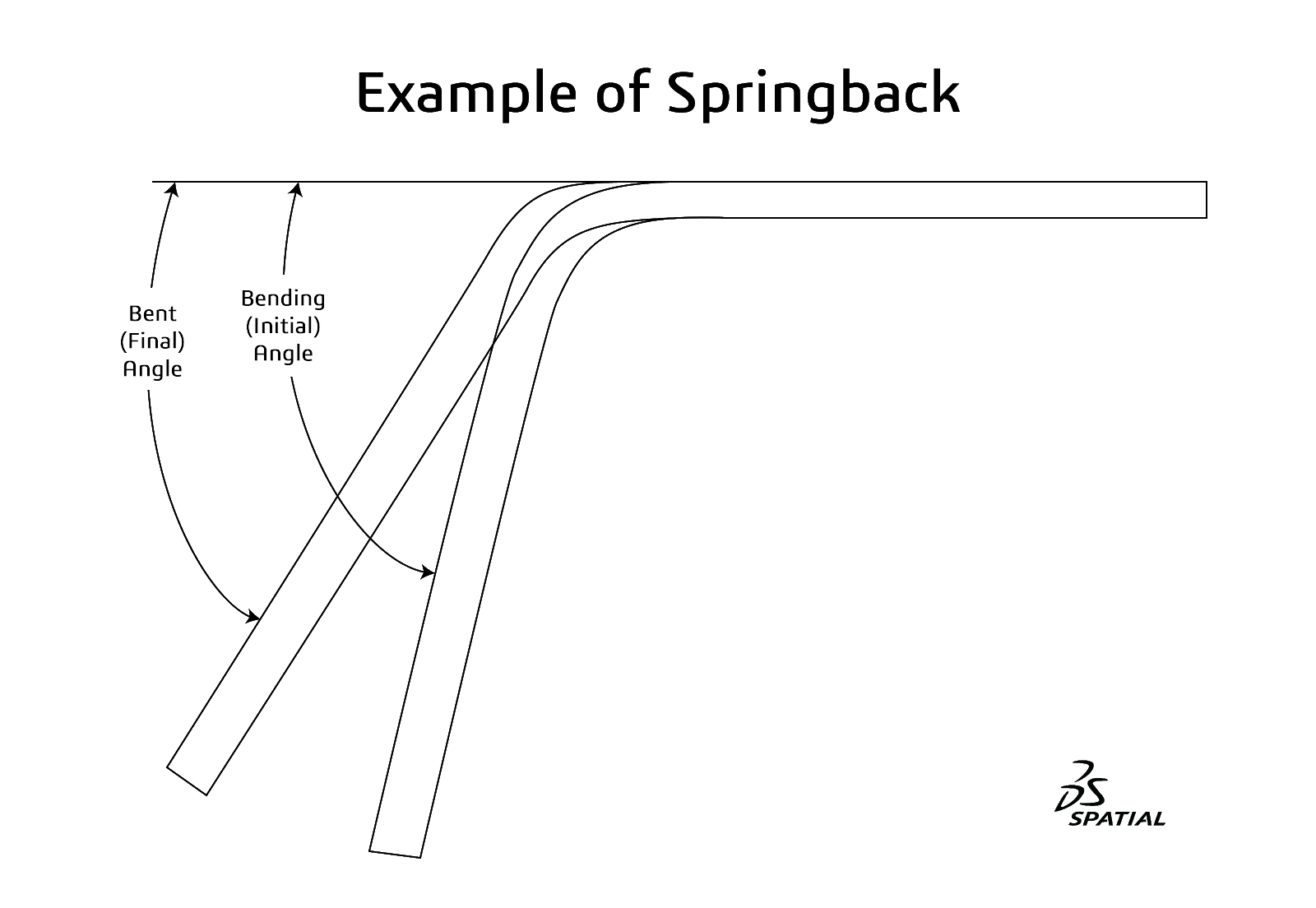

This phenomenon results in a deviation of the real product geometry from that defined in the design.

Finite element simulation of springback in sheet metal forming.

Several physical parameters as well as numerical influence this phenomenon and its numerical prediction.

Fe finite element simulation of sheet metal forming is an important means to reduce the number of experiments and optimize the process 15 16 17 18.

Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube.

Today the metal forming industry is making increasing use of simulation to evaluate the performing of dies processes and blanks prior to building try out tooling.

Modern automotive concepts demand a weight reduction by using high strength materials and excellent crash performance which requires innovative simulation techniques.

Proceedings of the eccomas 2000 complas vi european congress on computational methods in applied sciences and engineering barcelona spain 2000 cd rom.

Collard numerical simulation of springback in sheet metal forming.

Finite element simulation of sheet metal forming is a well established tool which is used in industrial practice to evaluate geometrical defects caused by elastic springback.

Bending of sheet metal is one of the widely used industrial processes especially in the automobile and aircraft industries.

Finite element analysis fea is the most common method of simulating sheet metal forming operations to determine whether a proposed design will produce parts free of defects such as fracture or wrinkling.

Springback can be defined as an elastically driven change of shape of the deformed part upon removal of external loads.

2 the results showed negative springback for sheet tensions near the material yield stress contrary qualitatively to all experimental observations.

This paper describes new techniques for the sheet metal forming simulation using a local interpolation for tool surfaces proposed by nagata simple local interpolation of surfaces using normal vectors.

Sheet metal forming is widely used in automotive aviation packaging and household goods.

The first simulations used numerical parameters typical of those in forming analysis.

Most sheet metals undergo a combination of bending stretching unbending and reverse bending during the forming process accurate estimation of spring back in these industries is important demands in bend angles can be within a narrow range.

It is most popular for the manifold technical feasibilities in manufacturing high precision mass production and short processing time.

A uniform mesh consisting of 150 plane stress elements for r 9 5 mm and five integration points through the thickness fig.